In industries like pharmaceuticals, food production, and environmental testing, the demand for accurate measurements of oxygen is crucial. The global oxygen analyzer market is expected to reach $2.4 billion by 2026, driven by advancements in technology and the need for precise quality control. An Oxygen Analyzer plays a vital role in ensuring safety and compliance, especially in high-stakes environments.

Yet, choosing the right Oxygen Analyzer can be a complex task. Various models offer different features, precision levels, and price ranges. A report by Market Research Future indicates that portable oxygen analyzers are likely to witness the highest growth, hinting at a need for mobility in testing methods. However, many users find it challenging to navigate the options available, leading to purchases that may not meet their specific requirements.

Investing in an Oxygen Analyzer should be thoughtful. Users must balance cost with the need for accuracy and reliability. While some products boast advanced capabilities, not all may be necessary for your application. Think critically about what features are essential for your industry. With the right information, selecting an Oxygen Analyzer tailored to your needs becomes a more achievable goal.

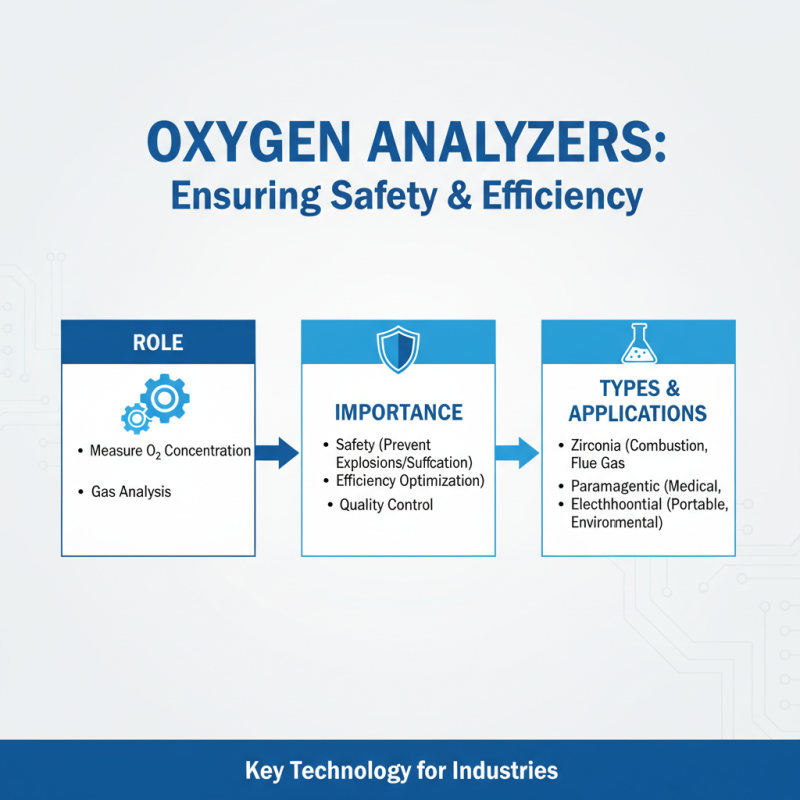

Oxygen analyzers play a crucial role in various industries. They measure the concentration of oxygen in gases. This helps ensure safety and efficiency in operations. Different types of oxygen analyzers serve distinct applications.

There are two main types of analyzers: handheld and stationary. Handheld units are portable and ideal for fieldwork. They are easy to use and provide quick readings. Stationary analyzers, on the other hand, are more suitable for continuous monitoring in fixed locations. These units can be more complex but offer detailed data and analysis.

When selecting an oxygen analyzer, consider the application. Different environments may require specific features. For instance, if accuracy is crucial, look for models with advanced sensors. Always check calibration requirements, too.

Tips: Conduct regular maintenance checks. This helps ensure accurate readings and prolongs the analyzer's lifespan. Moreover, consider investing in training for users. Proper use can prevent errors and improve safety. Always refer to the operating manual for specific guidance.

When choosing an oxygen analyzer, several key features are crucial. Accuracy and precision are paramount. Look for models that offer reliable and consistent readings. It is important to assess the calibration method as well. Some analyzers require manual calibration, while others adjust automatically. Automatic calibration can save time but may not always provide the best precision.

Portability is another aspect to consider. A compact and lightweight analyzer is more convenient for field use. Battery life also matters; a device with a longer-lasting battery ensures uninterrupted operations during critical tasks. Additionally, user-friendly interfaces contribute to effective monitoring. It should be easy to read and interpret the data displayed.

Consider the measurement range and response time too. Different applications may require specific ranges and speeds. A slower response time can lead to delayed reactions in some situations. However, not all users need extreme sensitivity. Think about your specific applications and environments to determine what suits you best. Remember to evaluate the features that truly matter for your needs rather than getting lost in every detail.

| Model | Measurement Range | Accuracy | Response Time | Battery Life | Price Range |

|---|---|---|---|---|---|

| Model A | 0 - 100% | ±0.1% | < 5 seconds | 200 hours | $300 - $500 |

| Model B | 0 - 25% | ±0.2% | < 3 seconds | 150 hours | $150 - $300 |

| Model C | 0 - 100% | ±0.05% | < 2 seconds | 300 hours | $500 - $800 |

| Model D | 0 - 40% | ±0.3% | < 6 seconds | 100 hours | $100 - $200 |

| Model E | 0 - 21% | ±0.1% | < 4 seconds | 250 hours | $250 - $450 |

Oxygen analyzers play a crucial role in various industries. A recent report from the International Society for Measurement and Control states that these devices have grown by 15% in demand over two years. This trend emphasizes their importance in ensuring safety and efficiency.

When looking at the top models of 2026, a few key features stand out. Many analyzers now offer real-time data. This can help professionals respond quickly to changes in oxygen levels. Advanced sensors allow for accurate readings, but they can be sensitive to environmental factors. Users should be aware of this potential inaccuracy.

Price is another significant factor. While some models are budget-friendly, others come with high-end features. A 2023 study indicated that nearly 30% of users reported budget constraints. It's essential for buyers to weigh features against their needs. Balancing quality and cost can be challenging. Some models may not perform well under extreme conditions, raising concerns for reliability.

Understanding industry standards and calibration for oxygen analyzers is crucial for their effective use. These devices play a vital role in various sectors, including environmental monitoring and healthcare. Accurate measurement of oxygen levels ensures quality control and safety. Calibration methods are not uniform; they vary by application. Regular recalibration is often necessary to maintain accuracy.

Calibration involves comparing the analyzer readings to known standards. This process can be tricky. Environmental factors may introduce variations, affecting the results. Users must consider factors like temperature and humidity. Inconsistent performance can lead to misinterpretations of data. Default settings may not suit every situation, leading to potential errors.

Adhering to industry standards is essential for compliance and reliability. However, not all users prioritize this aspect. Some may overlook routine checks, trusting their equipment too much. It’s easy to forget that devices require maintenance. Investing in proper calibration procedures is therefore beneficial. Calibration should never be seen as an optional task; it’s a necessity.

Investing in an oxygen analyzer can yield significant benefits. In industries like healthcare and manufacturing, oxygen levels are critical. According to a report by MarketsandMarkets, the oxygen analyzer market is projected to reach $1.5 billion by 2025. This shows a growing recognition of the need for precise measurements.

The cost of an oxygen analyzer varies, generally ranging from $500 to $5,000. While the upfront investment may seem high, the cost-effectiveness is evident. Poor oxygen management can lead to product spoilage or health risks. These factors can escalate operational costs significantly. A study found that maintaining optimal oxygen levels in food production can reduce spoilage rates by up to 30%.

However, it's important to recognize potential pitfalls. Not all models provide accurate readings, and maintenance costs can add up. Regular calibration is necessary to ensure reliability, and this can be an additional expense. Some users report feelings of uncertainty when it comes to choosing the right model. Industry statistics indicate that around 20% of oxygen analyzers require frequent servicing, leading to unexpected downtime.