Oil in Water Sensors: A Comprehensive Analysis of Working Principles and Operation Techniques

In today's era with increasingly stringent requirements for water quality, Oil In Water Sensor, as key devices for monitoring the content of oil substances in water, play an indispensable role in many fields such as environmental protection, industrial production, and water quality monitoring. A deep understanding of their working principles and operation techniques is of great significance for ensuring their efficient and accurate operation.

Working Principle: Ultraviolet Fluorescence Method as the Mainstream

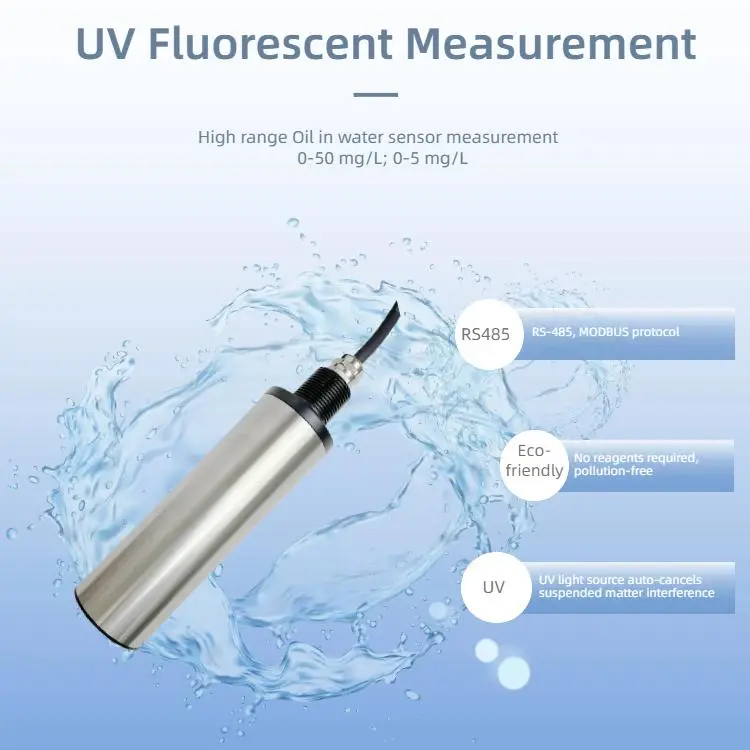

Currently, there are various working principles for oil in water meter, among which the ultraviolet fluorescence method is widely used. Take the LMS-OIL100 OIW sensor of Luminsens as an example, which adopts the principle of ultraviolet fluorescence analysis. In petroleum and its products, aromatic compounds with benzene rings and compounds with conjugated double bonds have characteristic absorption of ultraviolet light. When these substances absorb ultraviolet light, molecules will transition from the ground state to the excited state. When the molecules return from the excited state to the vibrational energy level of the ground state, they will release the absorbed energy in the form of fluorescence and emit molecular fluorescence. Moreover, within a certain concentration range, the fluorescence intensity is proportional to the content of petroleum.

Specifically, the aromatic hydrocarbons in petroleum can generate fluorescence under the excitation of ultraviolet light, and the sensor calculates the value of oil in water based on the intensity of the fluorescence. This method has the characteristics of high sensitivity. It can detect soluble and emulsified oils and can detect oil content as low as the ppb level. It is suitable for various complex water quality measurement scenarios such as oilfield monitoring, industrial circulating water, condensate water, wastewater treatment, and surface water stations. Compared with other commonly used methods, the fluorescence method is more efficient and fast, has better repeatability, and can realize online real - time monitoring.

Operation Techniques: Key Points in the Whole Process from Installation to Maintenance

Installation Link: Location and Method Determine Accuracy

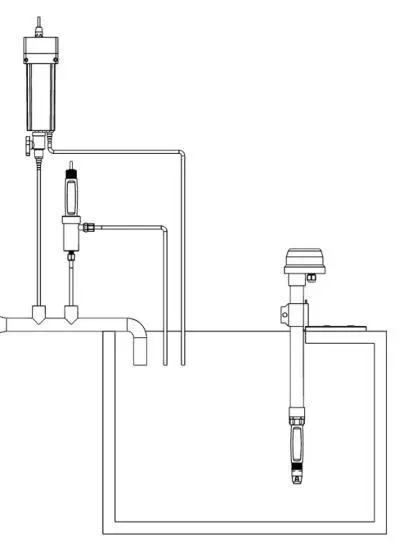

When installing a water - oil sensor, the selection of the installation location is extremely crucial. The sensor should be avoided to be installed in areas with rapid water flow, easy to generate vortices or with a large number of bubbles. These situations will interfere with the measurement results and lead to inaccurate data. At the same time, it should be kept away from sewage outlets, mixing devices, etc. to reduce the interference of external factors on the sensor. Generally, it is more appropriate to select an area with stable water flow, no violent disturbances and easy access for installation.

In terms of the installation method, it is necessary to operate strictly in accordance with the sensor instruction manual. If it is a wall - mounted sensor, appropriate screws and brackets should be used to fix it firmly; if it is an insert - type sensor, it should be accurately inserted into the preset pipeline or pool, and ensure that the head of the sensor is completely immersed in water to ensure that it can fully contact the water body and obtain accurate data.

Calibration Operation: The Cornerstone to Ensure Accurate Measurement

Calibration is a core step to ensure the measurement accuracy of oil in water analyzer. Before actual testing, the sensor must be calibrated according to the guidelines provided by the manufacturer. During the calibration process, the accurate preparation of standard oil samples is of vital importance. The concentration of the oil samples should be stable, and it is necessary to resolutely avoid using expired or deteriorated oil samples. Only when the calibration is accurate can the sensor output reliable data in subsequent actual measurements.

Daily Maintenance: Extend Service Life and Ensure Performance

During the daily use of the sensor, regular maintenance is indispensable. Since suspended solids, algae and other impurities in water are extremely easy to adhere to the sensor probe, which will affect the detection accuracy. Therefore, it is necessary to regularly clean the impurities on the probe surface with a soft brush and special cleaning agent. Special attention should be paid to avoiding the use of sharp tools to damage the probe during the operation. At the same time, calibrate the sensor according to the specified cycle, compare with standard oil samples or standard solutions. Once the deviation between the measured value and the standard value exceeds the allowable range, calibration adjustment should be carried out in a timely manner. In addition, the connection wires, sealing parts, etc. of the sensor should be regularly inspected to check whether there are aging, damage or poor sealing. If there are problems, the damaged parts should be replaced in a timely manner to ensure the long - term stable operation of the sensor.

Water - oil sensors provide strong support for water quality monitoring with their unique working principles. And correctly mastering the operation techniques, doing a good job in all aspects from installation, calibration to daily maintenance, is the key to giving full play to their performance, ensuring accurate and reliable data, and helping the sustainable development of fields such as environmental protection and industrial production.

Our Oil In Water Sensor features a single UV light source, automatically eliminating interference from suspended substances for stable and reliable measurements. No reagents, no pollution, being economical and environmentally friendly. It enables uninterrupted online water quality monitoring, with automatic compensation for turbidity disturbances and an automatic cleaning function, ensuring stability even for long - term monitoring. Calibrated before leaving the factory, plug - and - play, and equipped with a cleaning brush for less maintenance, easily facilitating water quality management!