The "Systematic Solution" for Multi - Parameter Water Quality Monitoring — Insights from the Evolution of Online Touch - Screen Analyzers

From “Indicator Pieces” to “Ecological Decoding”

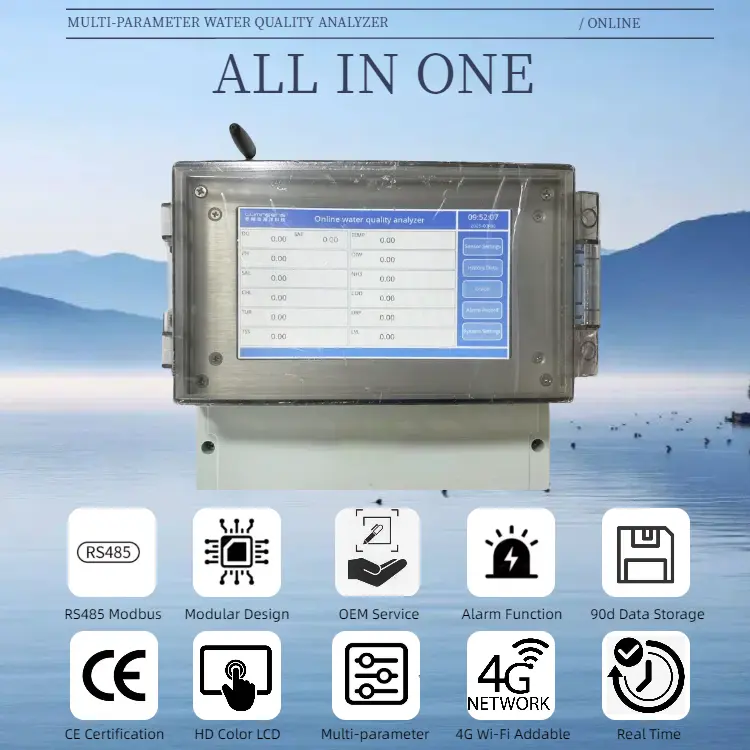

In the precision - driven evolution of water environment governance, water quality monitoring has transcended “point - like observation” of single parameters, entering an era of “systematic decoding” through multi - dimensional collaboration. As eutrophication in rivers demands simultaneous analysis of DO, pH, and turbidity correlations, and corrosion risks in industrial circulating water rely on the coupling of conductivity and hardness, the “data silo” flaw of traditional decentralized monitoring devices has become increasingly prominent. The Online Touch Screen Water Quality Multi-Parameter Analyzer (LMS - OA200T), as a mature technical solution in the industry, provides a replicable model for the efficiency revolution in water quality monitoring through “integrated architecture + intelligent interaction + scenario - specific adaptation”.

I. The Scientific Underpinning of Multi - Parameter Monitoring: Why “1+1>2”?

Water quality is a dynamic coupling of physical, chemical, and biological processes:

- pH and Corrosion: When pH < 6.5, the corrosion rate of metal pipelines increases exponentially;

- Dissolved Oxygen (DO) and Biochemical Reactions: DO > 2mg/L is fundamental for aerobic microbial metabolism, and a sudden drop in DO may indicate an algae bloom or sewage impact;

- Conductivity and Pollution Tracing: A sudden change in conductivity (e.g., from 200μS/cm to 1000μS/cm) often signals illegal discharge of industrial wastewater (containing high - salt pollutants).

Monitoring a single parameter is like “viewing a leopard through a tube”, while the core value of multi - parameter collaboration lies in reconstructing the “cause - effect chain” of water quality changes: For example, a continuous drop in DO, a rise in turbidity, and a slight drop in pH in a river, combined with meteorological data (high temperature and little rain), can infer the chain reaction of “algal bloom → death and decomposition → oxygen consumption + acid production”, providing precise basis for emergency responses (such as algae control and oxygenation).

II. Breaking Industry Pain Points in Device Design: From “Functional” to “User - Friendly”

1. Interaction Revolution: How Does the Touch Screen Reshape Maintenance Efficiency?

The essence of the 7 - inch touch screen is “flattening of operation logic”:

- Traditional instruments require debugging via “buttons + codes” (e.g., entering the “CAL” command to calibrate electrodes), taking 15–30 minutes;

- The touch - screen device supports visual wizard operations (click “Calibrate” → automatic electrode type recognition → one - click completion), compressing the time to within 5 minutes, enabling even non - professionals to get started quickly.

This “low - threshold interaction” directly alleviates the industry's shortage of maintenance talent (statistics show a 30% shortage of professional maintenance personnel in the water quality monitoring field).

2. Plug - and - Play: The “Industrial - Grade Evolution” of Sensor Maintenance

The industry value of the “hot - swap” technology lies in the dual dimensions of “cost reduction + production protection”:

- Cost Reduction: Traditional sensor replacement requires power - off, wiring disconnection, and restart (process exceeding 1 hour), while the hot - swap design compresses the time to 5 minutes, reducing maintenance labor costs by 70%;

- Production Protection: For continuous production industries such as chemical engineering and power generation, if sensor failures cause shutdowns, losses can reach tens of thousands of yuan per hour. Plug - and - play enables “maintenance without shutdown”, reducing production interruption risks by 95%.

3. Data Closed - Loop: Seamless Connection from “Collection” to “Decision - Making”

The compatibility of the Modbus RS485 protocol allows the device to become a nerve node in the “smart water network”:

- Integrating with SCADA systems: Real - time transmission of multi - parameter curves (such as the DO - pH dynamic correlation graph in the bioreactor of a wastewater treatment plant) to assist operators in precisely controlling aeration and chemical dosing;

- Incorporating into IoT platforms: Historical data (supporting storage of over 100,000 entries) can deduce water quality change patterns (such as the impact model of rain - induced sewer overflows on wastewater treatment plants), providing a basis for long - term planning.

III. Scenario - Driven Cultivation: From “General Monitoring” to “Precise Regulation”

1. Municipal Water Supply: Guarding the Final Line of the “Water Vein”

In water treatment plants, the device simultaneously monitors pH, residual chlorine, turbidity, and conductivity of the finished water:

- Residual Chlorine Linkage Control: When residual chlorine < 0.3mg/L (the minimum requirement at the end of the distribution network), the chlorination pump is automatically triggered for supplementary dosing, ensuring disinfection effectiveness;

- Space Adaptation: The compact design of 180mm×230mm×100mm allows wall - mount installation in pump rooms, secondary water supply stations, and other narrow spaces, compatible with the renovation of existing facilities.

2. Wastewater Treatment: The “Digital Brain - Machine Interface” of Biochemical Systems

The bioreactor in a wastewater treatment plant is the core battlefield of parameter games:

- DO - ORP Collaborative Regulation: When ORP (oxidation - reduction potential) drops to - 100mV (the critical value for nitrification), the aeration rate is automatically increased to avoid nitrification stagnation;

- Abnormal Warning: If pH drops suddenly (<6.5) and conductivity surges (>800μS/cm), the system determines an “acidic wastewater impact” and triggers an emergency diversion procedure to protect the microbial community.

3. Industrial Circulating Water: The “Protective Barrier” for Equipment Lifespan

In industries such as steel and thermal power, the corrosion and scaling risks of circulating water are directly related to equipment lifespan:

- Corrosion Index Modeling: Through monitoring conductivity, pH, and hardness, the “Langelier Index” (measuring scaling/corrosion tendency) is constructed. When the index > 0.5 (scaling risk), water softening is automatically initiated;

- Customized Expansion: An optional “online hardness electrode” enables real - time monitoring of calcium and magnesium ion concentrations, precisely controlling the dosage of scale inhibitors and reducing chemical costs by 30%.

IV. Industry Trends: The “Demand Code” Behind Technological Iteration

The continuous optimization of this device reflects three evolutionary logics in the water quality monitoring industry:

- Wave of Integration: Evolving from “single - parameter instruments” to “multi - parameter terminals”, device forms are moving toward “functional complexes”, driven by cost reduction and efficiency improvement (a single device integrating 5 sensors reduces hardware costs by 40% and maintenance costs by 60% compared to traditional solutions).

- Intelligence Penetration: Features such as touch - screen interaction and automatic calibration essentially represent “reconstructing the human - machine relationship” — adapting devices to human operating habits rather than the other way around, a key strategy to alleviate the “shortage of professional talent”.

- Scenario - Driven Cultivation: The proliferation of OEM customization services means devices must deeply match the “special genes” of niche sectors:

- Aquaculture: Requires high - frequency Do Monitoring (1 second/time), with a customized “fast - response mode”;

- Laboratory Scenarios: Pursuing 0.01 pH precision, with a developed “high - precision calibration module”.

From “Monitoring Tool” to “Governance Engine”

The mature application of online touch - screen water quality multi - parameter analyzers is not only a technological iteration but also an upgrade in industry thinking. When water quality monitoring truly achieves “multi - parameter collaboration, intelligent management, and scenario - specific adaptation”, the “precision - based governance” of water environments gains a viable fulcrum. In the future, with the deep integration of IoT and AI technologies (such as AI - based early warning of algae blooms based on multi - parameter data), such devices will become the nerve endings of the “smart water network”, continuously empowering every subtle link in water ecosystem protection.